Brickworks Vande Moortel celebrates 160th birthday

Brickworks Vande Moortel was founded in 1864 in the Scheldt Valley and celebrates its 160th anniversary this year, still as a family business. For 160 years, Vande Moortel has been creating IMPACT with facing bricks and clay pavers. Celebrating this birthday, the company takes a moment to look into the future of building with these sustainable products. IMPACT therefore stands as an acronym for the building blocks that Brickworks Vande Moortel stands for and with which the company continues to build on the future.

Click and discover how Brickworks Vande Moortel responds to each of these 6 key building blocks:

Click on the bar and discover Innovation

Innovation is in our DNA at Vande Moortel

Dedication to innovation and product development has been ingrained at Vande Moortel since its establishment in 1864. Throughout its 160-year history, the brickworks has always integrated the very latest technologies into its production processes and product development.

- In 1950, we made the pioneering move of switching from a traditional field kiln to a tunnel kiln: we were the first to do so in Belgium and the surrounding countries, at a time when almost all other manufacturers were switching to an annular kiln.

- Vande Moortel was also the first European manufacturer to produce class A and A+ moulded clay pavers.

- Our R&D department is constantly working on new developments and product innovations to enable us to continue to satisfy market demand.

20 years of ecologically optimised ECO-7-size bricks

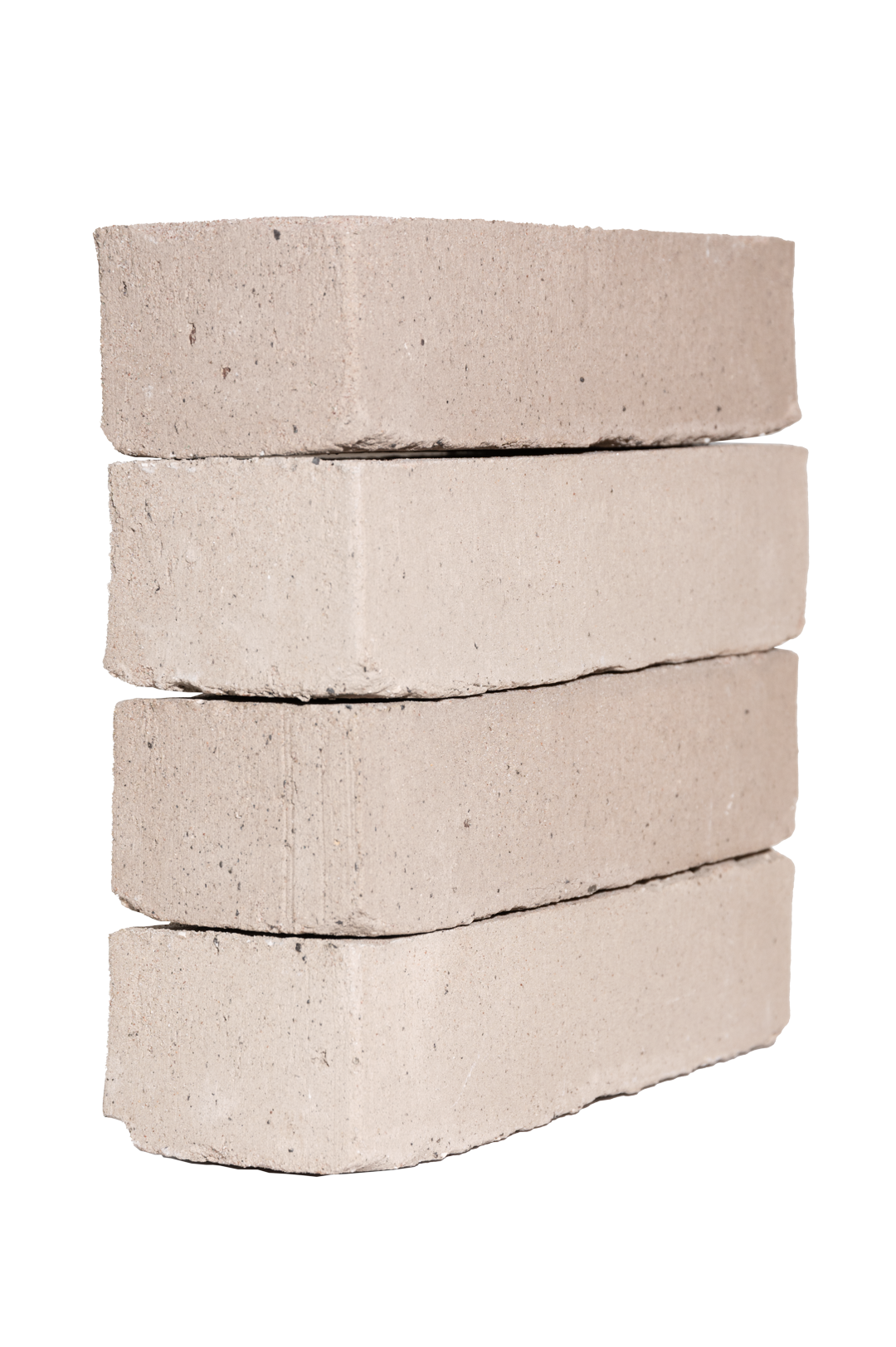

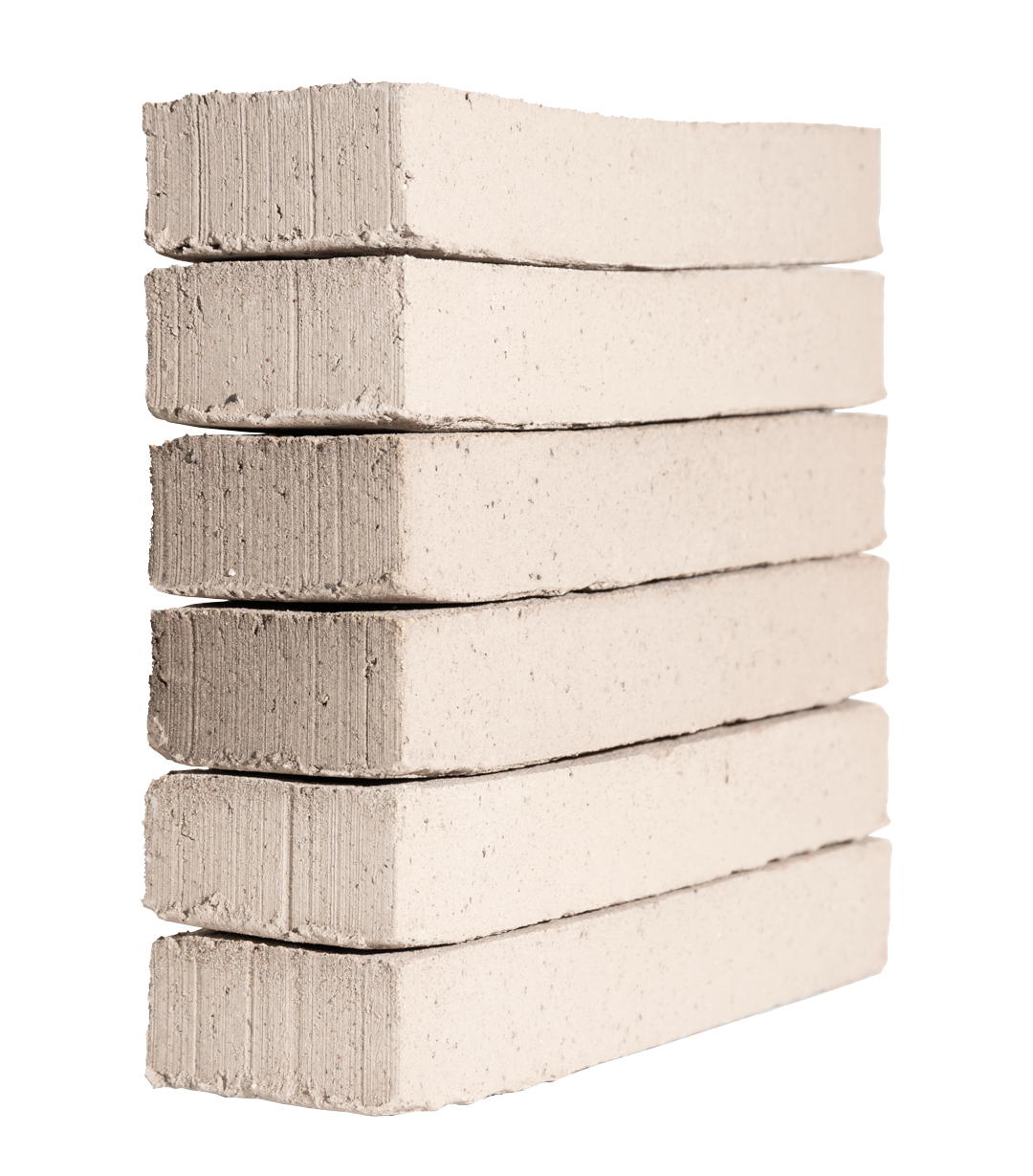

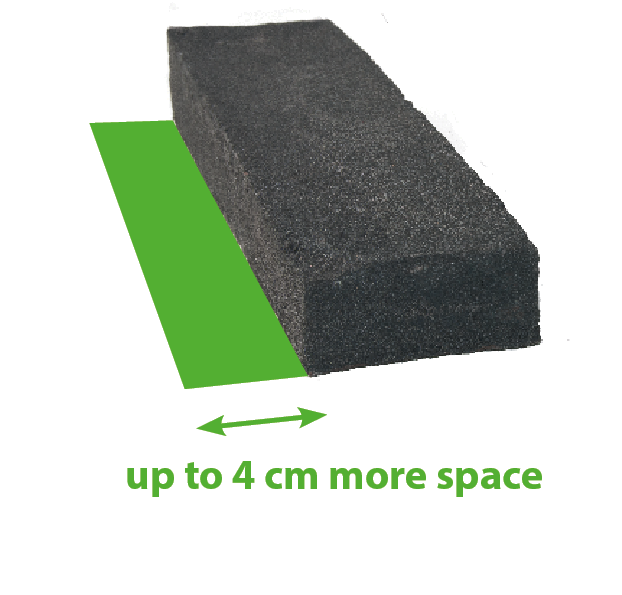

In 2004, Vande Moortel launched its most important product innovation which substantially reduced the CO2 emissions generated during the production of facing bricks and clay pavers. Brickworks Vande Moortel was the first manufacturer to switch from a traditional facing brick with a thickness of 10 cm to a thickness of 7 cm which nowadays we refer to as the ECO-7-size format.

We are continuously adding the ecological ECO-7-size to our whole product range: this year, we launched the Ancienne Belgique 7 clay paver. Almost all facing bricks are available in the ECO-7-size format and from now on, with the introduction of the Ancienne Belgique 7, that applies to the whole range of clay pavers too. Each year, the number of products in this format continues to increase. Our goal is to offer all products from our range in Belgium in the 7 cm format from now on and to systematically realise this transition in our export markets too.

Discover everything you need to know about the optimized ECO-7-size-format

Advantages of the ECO-7-size format

|

|

30% reduction of CO2 emission |

|

|

Optimised price-quality ratio |

|

|

Can be processed using traditional techniques |

|

|

The same quality and lifespan as a conventional format |

|

|

More efficient transport |

|

|

Fewer raw materials used for production |

|

|

Lower energy consumption during production |

H2O Natural Clay Paving

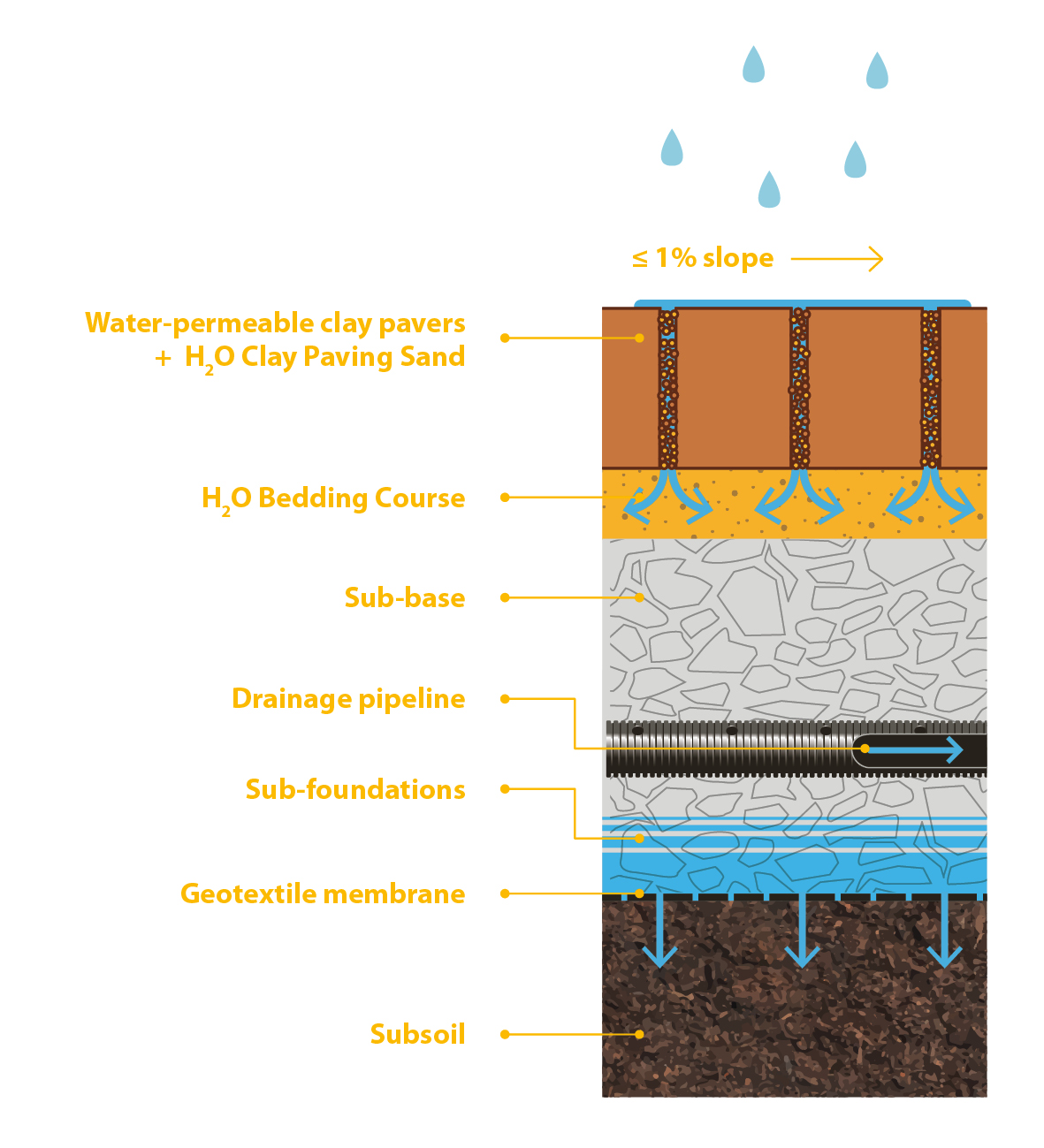

With the innovative H2O Natural Clay Paving principle, we introduced a water-permeable paving technique that can be combined with any clay paver from the range. This principle allows rainwater to infiltrate into the ground on the spot. We created H2O Natural Clay Paving sand for this purpose: this strong, durable and permanently water-permeable joint filler allows rainwater to infiltrate into the ground on the spot.

Discover everything you need to know about H2O Natural Clay Paving

brickZ

This sustainable and innovative spinoff was created by Brickworks Vande Moortel by combining our knowledge and experience with sustainable developments of partners and other startups motivated by the same principles. The creation of brickZ®as a new brand and company was the logical next step for our sustainability ambitions after pioneering the ecological ECO-7-size concept back in 2004. brickZ presents an extensive collection of brick slips called thin brickZin which – besides brick slips from The Vande Moortel Collection – we have also introduced other collections and product innovations such as The Color Collections and the zero waste brickZ. brickZ activities also include other innovative, sustainable and circular concepts and products such as the reusableZ and Sun & privacy screenZ. The latest Circular brick is a brand new product that is made entirely from secondary raw materials from our own residual flows, infrastructure works or other production units.

Discover the full brickZ range here

Click on the bar and discover Multifunctionality

Unique colours & sizes

Facing bricks and clay pavers are extremely multifunctional in the sense that there is a huge range of possibilities in terms of applications, bonds, colours and dimensions. Our product range includes a wide selection of colour variations, finishes and formats in the various product categories to meet any requirement.

Discover unique colours & sizes in facing bricks

Discover unique colours & sizes in clay pavers

Multifunctionality further reinforced thanks to brickZ

What is more, we produce not just clay pavers and facing bricks but also brick slips for specific applications, making our products extremely versatile and able to meet a wide range of building requirements. Brick slips are particularly suitable for corbelling, corners and challenging design problems, for example. The other brickZ collections – like the reusableZ, sun & privacy screenZ and léém – further reinforce this multifunctionality

Versatile

The facing bricks and clay pavers are also versatile, making them suitable for use in a wide range of projects. Vande Moortel bricks are suitable for both smaller projects such as private homes, driveways and gardens and large-scale projects such as apartment blocks, school buildings, town squares and parks open to the public. Incidentally, facing bricks and clay pavers are not only used outdoors but are often continued inside in order to create a smooth transition in the form of an interior wall or a terrace that extends inside, for example. Besides terraces, squares or driveways, clay pavers are suitable for multifunctional use and are also perfect for steps, benches, borders or other applications.

Click on the bar and discover Performance

Meeting the highest quality standards

Performance is an essential aspect of Vande Moortel bricks. Our products are durable and able to withstand the test of time and various environmental factors, with a lifespan of more than 160 years. The strength and robustness of our bricks make them essential for solid structures. Besides aesthetics and sustainability, we also focus strongly on quality. We produce sustainable bricks using high-quality materials that are mined locally. DThe bricks produced in Oudenaarde always meet the highest quality standards and routinely exceed Belgian standards which are among the strictest in the world. For instance, our clay pavers have a very low level of water absorption while our facing bricks have a high compressive strength. In addition to the mandatory CE mark and the DoP declaration of performance, we also award the BENOR label to our products. This voluntary quality label is awarded to products that meet specific technical requirements and standards in Belgium, and provides independent and reliable certification for building products with specific technical characteristics.

Low water absorption

Clay pavers have a specific production process which produces a harder material with higher wear resistance and low water absorption. As a result, the clay paver produced is a durable material with a higher load-bearing capacity and suitable for horizontal use, making them ideal for parking areas and paving. The very low water absorption of class A en A+ pavers ensures that they absorb little moisture, thus reducing the risk of greening and frost damage.

Click on the bar and discover Architecture

Valued partnerships

Our collaboration with renowned designers, architectural firms and consultancy firms plays a central role at Vande Moortel. Thanks to these close collaborations, we learn from each other, which enables us to offer exceptional solutions and bring flagship projects to life. New colours and designs have been produced through consultation with architects and designers, such as the linea7 7045 or linea7 9002, for example. The Camargue variant, which was introduced recently for the SeptimA clay paver range, was also inspired by collaborating with various designers.

The subject of our latest product launch is the linea 2012 , a new shade that also meets the requirements of architects and designers. This salmon pink unsanded variant from our linea-series is ideal for accentuating architectural lines or clean linear designs in decorative brickwork. The soft salmon pink shade has now also been launched in the NATURE7 series This means that we have also extended this new colour shade to the ecological format. Demand for soft colours remains high, which is why we have also developed new grey shades in the ECO-7-size.

Click on the bar and discover Circularity

An inherently sustainable product thanks to natural raw materials...

- Long lifespan of 160 years or more and production using only natural raw materials and elements such as clay, sand, water, oxygen and fire.

- The clay is primarily extracted locally from around the brickworks itself, thus keeping transportation of the clay to a minimum.

- After extraction, the site is upgraded which can also promote biodiversity.

- Brick is an inert product that does not react with other substances or release any toxic or allergenic substances, so there is no risk of soil contamination either.

… that lends itself perfectly to circularity

…thanks to the recovery of secondary raw materials

To reduce the speed of operation of our own quarries, we regularly also use secondary raw materials such as loam and clay released from infrastructure works and construction projects. During the infrastructure works on the lock in Kerkhove, Vande Moortel recovered around 72,500 m³ of clay.. This raw material was released during the performance of these works and reused at the brickworks in Oudenaarde. Transportation by water via the Scheldt was used for all the transport movements, thus eliminating the need for 5,200 trucks.

… thanks to the recovery of an authentic product

The recovery and reuse of old bricks – known as reclaimed bricks– is becoming increasingly important in the context of circularity. There are countless examples where reclaimed brick has been reused in various applications in the same location or elsewhere, for restoration or new build projects, both for classic and modern projects.

Clay pavers also have a hugely circular character and can be reused several times, both in the same location for renovation purposes or in other projects. In Grote Markt in Sint-Niklaas , for example, the existing clay pavers from Vande Moortel will be carefully removed and reused to construct the new market square. Vande Moortel intends to market the pavers that are not reused in the renovation as reclaimed clay pavers.

Besides reusing products for their original function, we will also repurpose bricks via ‘urban mining’,for example. For this ‘secondary circularity’ bricks will be broken up into coarse rubble so that the material can then be given a new purpose by reusing them in the construction of paving and as a water-permeable infiltration layer. Brick rubble from demolition sites can also be recycled and reused as a foundation layer. The church garden at Saint Gertrude’s Church in Wetteren is a prime example of this type of reuse of existing materials where milled facing bricks and clay pavers have been used as a water-permeable infiltration layer. Milled brick was also reused as paving for the parking area at the Vande Moortel site.

Green Deals

Many sustainable and circular innovations originate from the Green Deals, with us still being actively involved as a company in an innovative learning network in order to share practical experiences with other construction companies, producers of building materials, local and regional authorities, private developers, researchers and other organisations.

Green Deal ‘Natural Gardens’

Vande Moortel – along with all the interest groups from the gardening sector – also supports the Green Deal Natural Gardens. By redeveloping our own site, we have turned an industrial site that used to be paved with concrete into a modern functional space that shows respect for nature. A total of more than 200 trees were planted and water-permeable paving was laid using brick rubble and pavers in conjunction with H2O Natural Clay Paving sand. By making the transition from our industrial site paved with concrete to a modern functional space that shows respect for nature and climate, we have become part of the Flemish government’s ‘Green Deal Companies and Biodiversity’.

Green Deal ‘Garden Streets’

Through the Green Deal Garden Streets, we have initiated a turnaround in Flanders in order to structurally create more garden streets. By bringing together municipalities, residents, businesses and other parties concerned, we want to create awareness, build up knowledge and offer practical support in order to turn ‘average’ streets into flourishing garden streets. Our aim in doing this is to realise no less than 1,000 garden streets by 2030.

The sustainable result of sustainable production

Besides developing sustainable products, Vande Moortel also uses ecologically sound production processes which rely on heat recovery, transportation by water, renewable energy and local extraction. Circular principles are the main aim in all aspects of the production process:

- Intensive renewal of kilns to efficient tunnel kilns with less energy consumption

- Maximum reuse of residual heat of the kilns thanks to recovered heat in the during kilns

- Maximum use of water transport via the Scheldt thanks to new loading quay, saving 3,000 trucks a year. We transport around 75,000 tons of goods via our inland waterways per annum.

- Maximum use of solar energy thanks to the installation of 2200 solar panels in 2021 and 1005 new solar panels in 2024, giving us a peak capacity of 1307 kWp peak power, enabling us to generate an output of 1,255 MWh per annum. Today, we cover 18% of our energy consumption by solar panels, with the ambition to increase this to 25% in short term.

Valuable repurposing of mining areas

The Brickworks’ former quarry pit on the right bank of the Scheldt is also being transformed into a whole area with high biodiversity values. The aim of Vande Moortel – through consultation with the various stakeholders – is to establish an area as a marshy wetland with high biodiversity values in respect of birds, amphibians, insects, reed beds and other valuable vegetation among others.

Click on the bar and discover Tradition

Tradition is one of the fundamental building blocks that have made Brickworks Vande Moortel what it is today, 160 years after it was first established. The story of our brickworks is deep-rooted in the 160-year tradition of firing bricks on the banks of the Scheldt. The Vande Moortel has proudly carried on with this craft for generations, with the heirs respectfully continuing to build on the work of their predecessors. The knowledge, techniques and passion that have been passed down over time are at the core of who we are today, 160 years later.

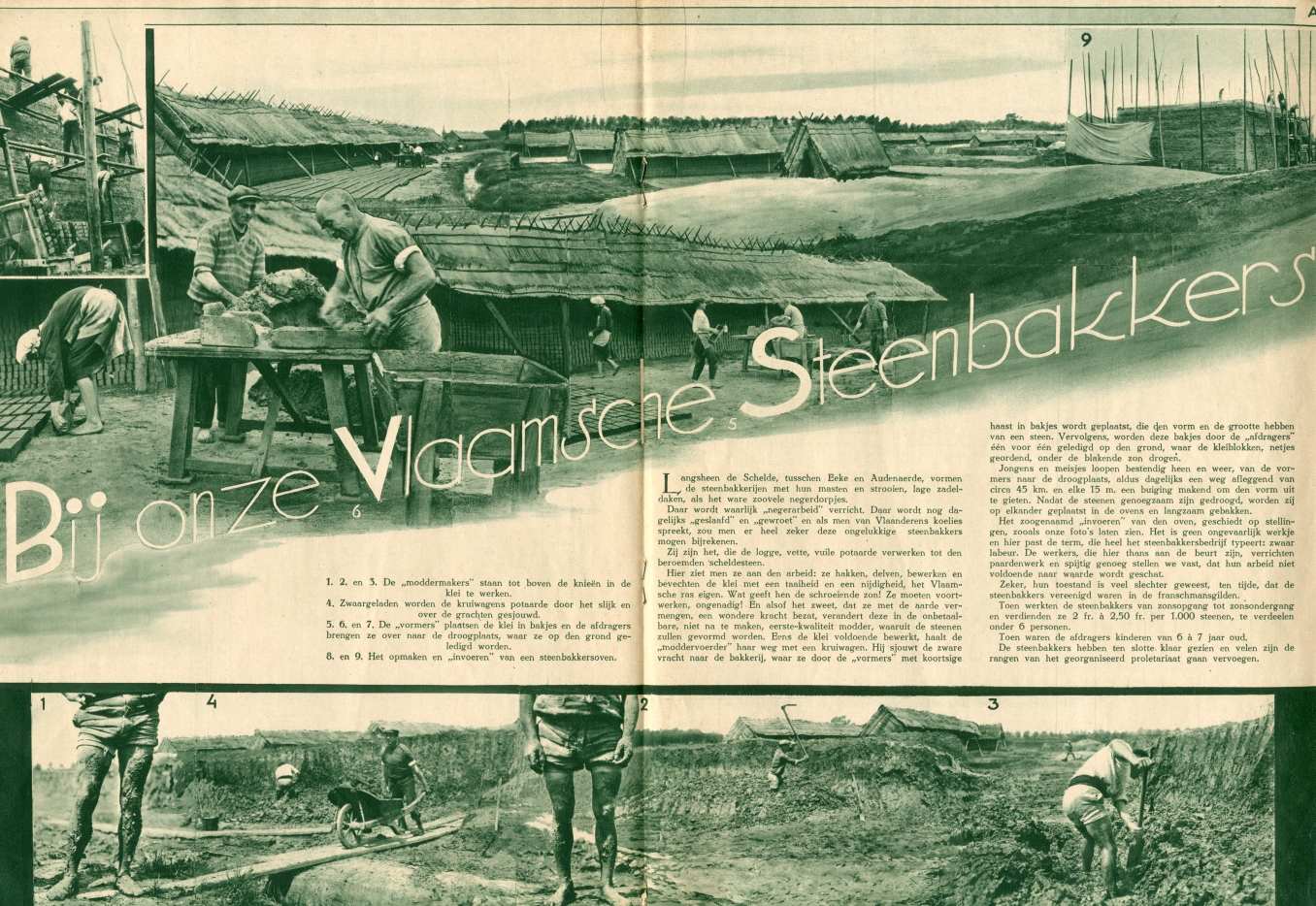

For centuries, the Scheldt burst its banks in winter, leaving behind a rich layer of clayey silt. This natural process that kept recurring over thousands of years resulted in a layer of clay metres thick, and formed the basis for the famous ‘Scheldt brick’ that was excavated from the Scheldemeersen between 1850 and 1950. After removing the top layer which was unsuitable because it contained too much organic material (topsoil), the clay was put into trenches approximately one metre deep. The bricks were made at the site where the raw material was excavated.

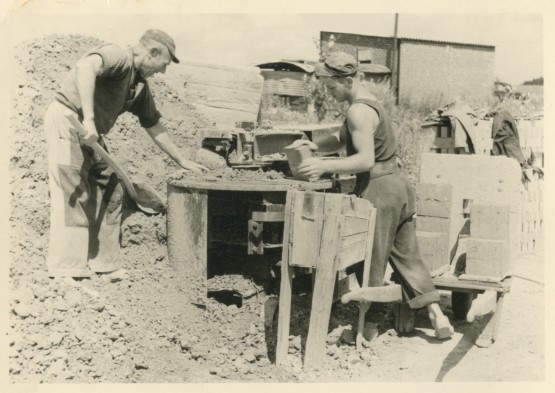

The process of making bricks involved intensive collaboration between various craftsmen, each with their own role and expertise. The ‘mud maker’ started off the process by kneading the soggy clay soil into a cohesive mass. The ‘supplier’ then used a wheelbarrow to transport the processed clay to the moulding table where the ‘moulder’ threw the clay with precision and strength into the moulds pre-coated with sand by the ‘off-bearers’, carefully pressed it down and levelled it off. The ‘off-bearers’ made sure that the bricks were laid out neatly on the ‘drying floor’, a carefully prepared piece of ground where the bricks could dry out. This was a crucial moment in the process because the quality of drying determined the durability of the brick.

After being left to dry in the open air for several days, the bricks were moved to low or drying houses where they were left to dry for a further 6 to 8 weeks in a ‘hack’. This lengthy process where each stage had to be carried out meticulously showed the dedication and craftsmanship of the brickmakers. A team of brickmakers would make approximately 500 to 600 bricks an hour by hand.

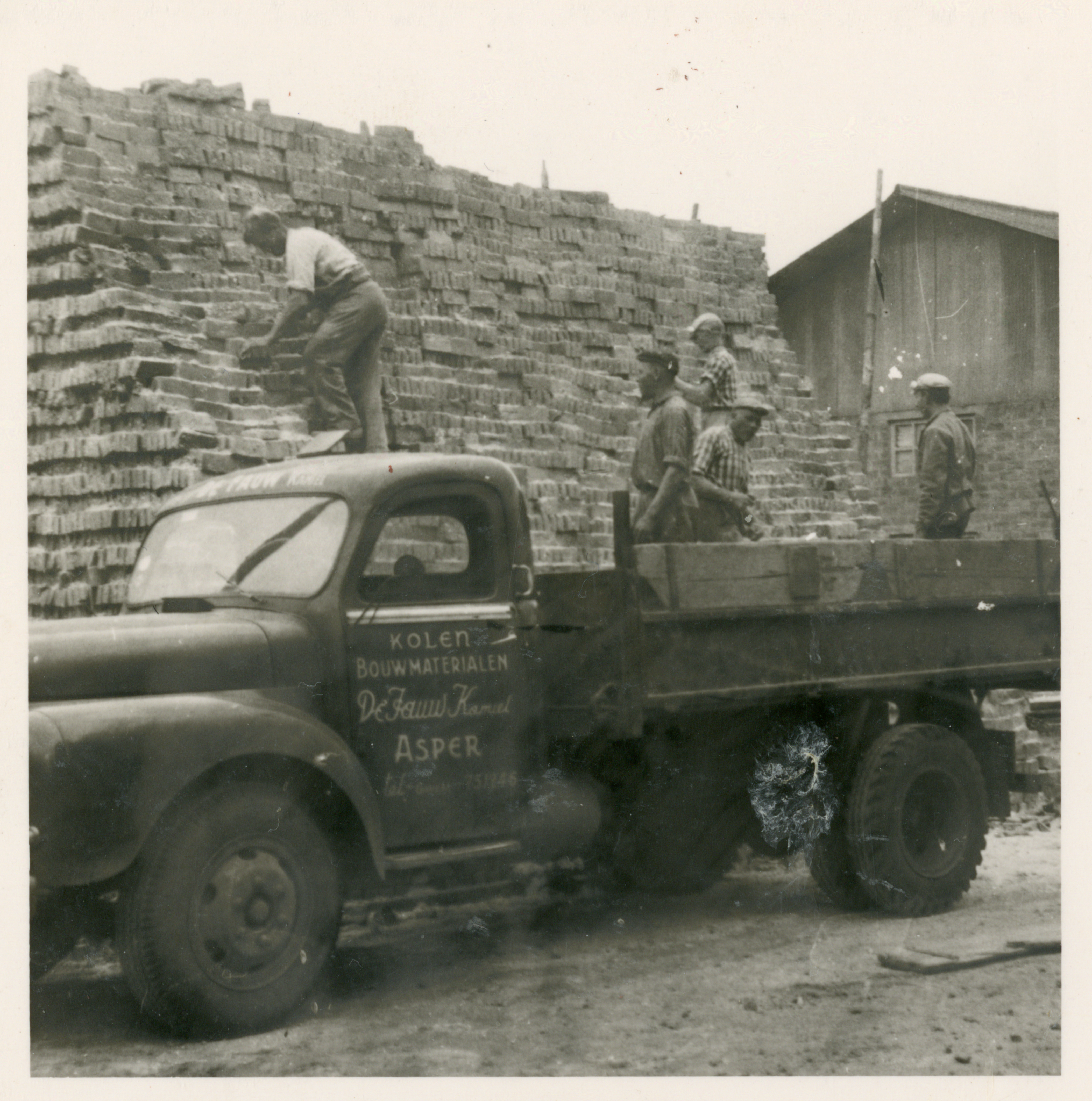

As soon as enough bricks had been produced and dried, the complex process of building the brick kiln in which the bricks would ultimately be fired could be started. The stacking of the bricks with space for placing coal between them was the job of the ‘setters’, and called for great skill and experience. In the meantime, the ‘firer’ took care of loading the kiln with coal and lighting the fire. To make optimum use of the heat, the outside of the kiln was carefully covered with mud by the ‘daubers’. The actual firing process took 6 to 8 weeks and after that, the kiln was dismantled and once the bricks had completely cooled down, they were ready to be transported.

The artisanal process described above shows how deep the tradition of brickmaking is anchored in the history of Brickworks Vande Moortel. Today, the family and the whole team honour this tradition by combining the old techniques with modern innovations as a result of which the brickworks continues to guarantee the high quality and sustainability of our bricks. The tradition of brickmaking on the Scheldt lives on in every brick that is produced, as a tangible reminder of a centuries-old craft and a constant source of inspiration for the future. With this rich history to look back on, we can now look ahead to an ambitious future led by the new generations, as already assured by the children and grandchildren of the Vande Moortel family. Just as important as this centuries-old tradition, are the teams of Brickmakers who are there every day to continue this artisanal production together with all sustainable innovations. Each brickmaker is part of the already achieved successes and of the future story of the brickworks.

Do you wish to be a part of our Brickmakersfamily? Discover our jobs.